Epoxy adhesives

Epoxy adhesive is considered one of the most significant adhesives in history, since the beginning of adhesive use. Epoxy adhesives are composed of epoxy resin, which exhibits various properties and characteristics depending on the resin grade and fillers added, such as metals and ceramics. These adhesives have been utilized in the industry for over half a century, offering excellent chemical and physical properties. Typically, they are produced in two components: resin and hardener.

What is a epoxy adhesive and its applications?

Epoxy adhesives are known for their strong bonding capabilities and resistance to chemicals, heat, and water. They are used in a wide range of applications, including construction, automotive, aerospace, marine, and electronics industries. Epoxy adhesives can be used to bond various materials like metals, plastics, wood, and ceramics. One of the primary advantages of epoxy adhesives is their ability to form a strong bond even under harsh conditions. They can also fill gaps between surfaces and provide excellent electrical insulation. However, they require careful handling due to their potentially harmful nature.

Specific characteristics and privileges the substance

Epoxy resin-based products have a wide range of applications, including coatings, paints, adhesives, and sealants for repairing metal surfaces. Upon drying, epoxy adhesives become hard and rigid, with drying times ranging from a few minutes to several hours. Generally, the faster an adhesive dries, the lower its final strength will be, and vice versa. One-component epoxy adhesives require heat activation and have a higher drying speed than two-component epoxy adhesives.

Strong and durable adhesion conditions

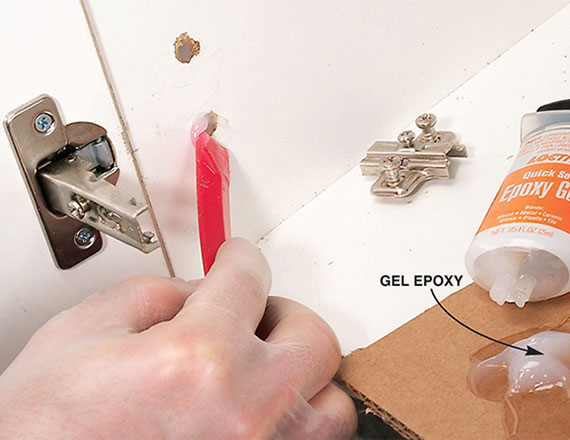

To ensure a strong and durable adhesion of epoxy glues, it is crucial to prepare and clean the surface before applying the glue. This applies not only to epoxy glues but also to other adhesives such as polyurethane adhesive, MS polymer adhesive, and silicone adhesives. Neglecting to prepare the surface properly can significantly impact the quality of the final adhesion. The longevity of epoxy adhesives is contingent upon the location and conditions in which they are stored. When stored under appropriate conditions, epoxy adhesives can typically remain effective for several years.

Advantages of epoxy glue

Epoxy glue have several advantages over other types of adhesives such as silicone and polyurethane.

Firstly, they experience a decrease in volume, or shrinkage, after drying which ensures that the adhesive remains in place and does not crack or break due to changes in temperature or pressure.

Secondly, epoxy adhesives do not release any gas during the drying process which makes them ideal for use in confined spaces.

They are also highly compatible with a wide range of materials and can adhere to many different surfaces, including metals, plastics, and ceramics.

Additionally, epoxy adhesives offer excellent chemical and corrosion resistance as well as high resistance to erosion. They are also suitable for use as insulation for electrical cables.

Unique features of epoxy adhesives compared to other adhesives

Epoxy adhesives are a superior type of adhesive due to their unique properties, including their ability to be drilled, turned, sanded, and ground. Additionally, they have the capability to absorb shock and vibration at the point of application, making them ideal for use in environments where these factors are present. Furthermore, epoxy adhesives prevent corrosion between dissimilar metals when used in such applications.

They have several advantages over mechanical fasteners. They operate faster than mechanical fasteners and are more affordable. Additionally, one of the significant benefits of epoxy resins is that no toxic substance is added or produced during the manufacturing process, providing greater safety when working with them.

Various types of epoxy adhesives and their applications

A. Metal epoxy adhesive

It is a specialized adhesive designed for bonding metal objects. It is a two-component glue that requires mixing two parts to form a strong bond. This type of glue is specifically formulated to bond various metals such as copper, iron, aluminum, zinc, titanium, steel, and brass. It is commonly used to repair holes or leaks in metal products and fill metal edges.

Metal epoxy glue provides excellent resistance to heat, water, and chemicals, making it ideal for use in harsh environments. This adhesive has two main features that set it apart from other products on the market. Firstly, it has an incredibly short drying time, allowing for full adhesion to be achieved quickly and efficiently. Secondly, this product is highly resistant to a variety of solvents and natural elements such as moisture, water, and air. Even after adhesion is complete, the volume of the glue will remain unchanged.

B. Fiberglass epoxy adhesive

It is a two-component adhesive composed of epoxy and hardener that is commonly used on fiberglass. This type of adhesive significantly enhances the resistance of fiberglass against thermal and mechanical factors. It is highly resistant to water and high temperatures, and does not face any rotting issues over time.

Fiberglass epoxy adhesives have numerous applications in various industries. These adhesives are extensively used in the production of composites, models, aviation models and their parts, monoliths, and the automotive industry. The unique features of fiberglass epoxy adhesives include high tensile strength, high thermal and chemical resistance, excellent adhesion to various surfaces, and very high resistance to wear.

C. Concrete epoxy adhesive

In the construction industry, concrete is a crucial material that provides strength and stability to structures and buildings. A significant scientific advancement in this industry is the development of concrete epoxy adhesive. This type of adhesive is specially designed to bond concrete surfaces together, creating a strong and durable connection.

Concrete epoxy adhesive is a versatile material that can be used to connect fresh concrete to old concrete mortars, creating extremely high tensile strength in concrete. It also has the ability to adhere well to various surfaces such as metal, brick, mosaic, and stone. Additionally, it offers moisture resistance, which helps in extending the life of concrete and structures. The ease of implementation of construction work is another advantage of using concrete epoxy adhesive.

D. Stone epoxy adhesive

In the constantly evolving world of construction and structural engineering, there is a growing demand for high-quality materials that can help build stronger, more durable, and aesthetically pleasing structures. One such material that has gained popularity in recent years is stone epoxy glue.

This adhesives have various uses in the construction industry. It is commonly used for implementing and installing stone on both interior and exterior surfaces of buildings. The adhesive can also be used for installing different types of stones on metal surfaces, including iron, aluminum, and steel. Additionally, it can be used for implementing ceramic tiles on all kinds of surfaces. Stone epoxy adhesive is also effective in installing construction parts on various materials such as metal, concrete, wood, blocks, and more.

E. Paste epoxy adhesive

It is a versatile adhesive that can be applied to various surfaces including metal, plastic, aluminum, fiber, plaster, and wood. What makes this adhesive interesting and desirable is its resistance to external factors such as water, cold, and heat. These factors do not affect the adhesive’s ability to stick and it will not fall over time.

This particular type of epoxy adhesive serves several key purposes, including repairing wear and tear as well as leaks in pipes that carry both water and gas, regardless of whether they are exposed to high or low temperatures. Additionally, this glue is effective at preventing leaks in both large and small industrial tanks, covering any damage to thin walls, and even mitigating the impact of surface scratches.

Iran’s epoxy adhesives

Iran is one of the producers, and exporters of epoxy adhesives in the world. This indicates that Iranian-made epoxy adhesive’s quality is indeed competitive with those produced by other countries. Iran’s chemical industry has a strong foundation in the production of high-quality epoxy adhesives.

The country has made significant investments in research and development, which has led to the creation of advanced epoxy adhesives that comply with international standards. These adhesives are extensively utilized across different sectors such as aerospace, automotive, construction, and electronics.

Purchasing epoxy adhesives from Iran

Purchasing epoxy adhesives from Iran can provide a cost-effective solution. Iran is recognized as a significant producer of petrochemicals, which are essential in the creation of epoxy resins. Consequently, the expenses incurred in obtaining raw materials for the production of epoxy adhesives are relatively lower in Iran compared to other countries. This results in a reduced cost of products for potential buyers.

Please do not hesitate to contact Iran Petroleum if you are looking for the best quality and price offer for epoxy adhesives produced in Iran.

In order to understand different types of epoxy resins and their applications please read other our article here: Epoxy Resin

Leave a Reply