Polyamide

Polyamide, commonly known as nylon, is a thermoplastic polymer introduced to the industry in the mid-1930s by DuPont engineers.

Since then, polyamide has been a suitable material in most industries, such as automobile manufacturing, the food industry, sports equipment, the carpet industry, and most importantly, the textile and clothing industry.

Polyamides are usually converted into fibers to be used. If you are willing to get familiar with the types of simple polyamide available in the industry, their characteristics, and their use, this article will help you.

What is polyamide?

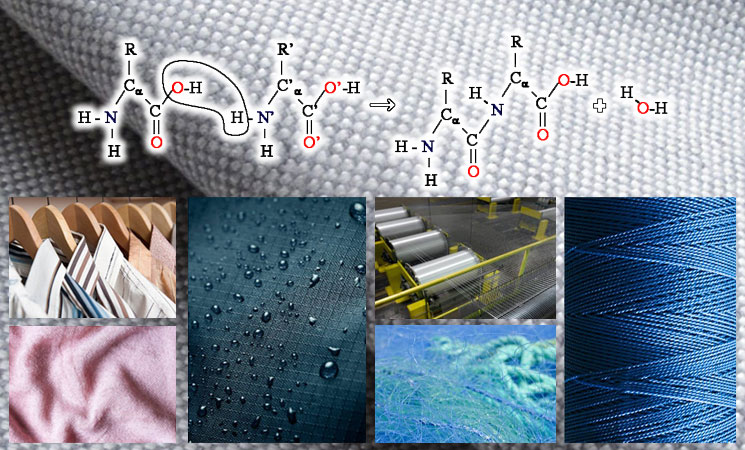

Simple polyamide is a polymer that includes amide groups (R-CO-NH-R) as an essential part of the polymer chain. These amide groups keep repeating. A simple polyamide with a high molecular weight is usually called nylon.

Simple polyamide is a crystalline polymer formed from the combination of a diacid and a diamine. In the mixture of these two monomers, the linking of molecules takes place through the formation of amide groups. The most crucial simple polyamide is nylon, which is considered a very flexible material. Today, simple polyamide is produced in the form of thin and long threads.

At first, simple polyamide was used to make parachutes and ropes in World War II, but later in the 40s, it gained its place in the clothing and fabric market. Due to its elasticity, this material achieved great success in the hosiery industry and quickly replaced silk stockings, which were expensive and less flexible.

Today, simple polyamide is used for many sticky clothes, such as women’s socks, pantyhose, swimwear, underwear, and high-quality and comfortable sports clothes.

Types of polyamides

Types of simple polyamide are usually named with a unique number placed in front of the polyamide name, and each one has its unique characteristics. In this section, we will introduce the types of simple polyamide.

1- Polyamide 6.6

This polyamide melts at a very high temperature and is resistant to abrasion. Hence, this polyamide works very well for making various car parts. But polyamide 6.6 also has its disadvantages. For example, it absorbs a lot of water, and its chemical resistance is weak. Since this simple polyamide is strong and has high heat resistance, it can also act as a thermoplastic.

2- Polyamide 6

This type of simple polyamide is somewhat crystalline and is very resistant to erosion. This simple polyamide is also resistant to chemicals such as acids and alkyl. However, the tensile strength of polyamide 6 decreases due to a water absorption of 2.4%.

3- Polyamide 6.10

Another type of simple polyamide is polyamide 6.10, which is resistant to chemicals and acids. This simple polyamide is more robust than almost any other nylon, so much so that it doesn’t break even under a salt like zinc chloride. This class of simple polyamide, which absorbs relatively less water, also shows good resistance in wet environments.

4- Polyamide 6.12

Polyamide 6.12 is one of the most expensive types of simple polyamide, which is resistant to heat but does not show high resistance to acids and bases. This polyamide is also unable to absorb a large amount of water.

5- Polyamide 4.6

This type of polyamide is very resistant to chemicals and crystallization. Many simple polyamides may lose some of their properties at high temperatures, but this does not include polyamide 4.6.

6- Polyamide 11

This polyamide is extracted from vegetable oil and is resistant to UV rays but not resistant to halogens and acids.

7- Polyamide 12

This type of polyamide can take any shape and size due to its high flexibility. However, this polyamide is considered one of the most expensive polyamides available.

8- Polyamide 6.9

This polyamide absorbs a minimal amount of moisture and melts at a much lower temperature than other types of polyamide.

Application of polyamides

Polyamide or nylon is the most considerable thermoplastic material in engineering industries. This material has different uses in every industry, which we will discuss in this section:

A. Automobile Manufacturing

At one time, metals were used for air intake parts in automobile manufacturing, but today these materials are made of polyamide 6. Replacing metals with nylon reduces the cost of production by 30% and the weight of parts by 50%.

Engine covers are also other products that are made using simple polyamide. In airbag housing, polyamide also causes the connection of parts and significant weight reduction compared to metal housings.

B. Production of polymer fibers

Polyamides are used in the production of polymer fibers, such as nylon and aramid fibers. These fibers are made from long polyamide chains and are usually solid and stable.

C. Making sports equipment

Polyamide is known for its high strength and elasticity, which is why it is often used for sportswear. Polyamide is also used to produce sports leggings due to its abrasion resistance to keep the legs tight and dry during exercise.

D. Making electrical circuit boards

Polyamides are used to produce automatic switches (MCCB) in electrical circuits. Polyamide allows thinner keys to be produced while increasing the electrical resistance rate to 100kA at 400V.

E. Production of fabrics, clothes, and carpets

Polyamide is very popular in the carpet industry due to its unique strength, stability, elasticity, and ease of cleaning. Also, polyamide fibers are used in the industry for the production of clothes and socks due to their meager price, and they are popular substitutes for cotton and linen.

F. Making pipes and hoses

Polyamides are used to produce pipes and hoses due to their high resistance to abrasion, impact, cracking, and bending. Polyamide tubes are also used as a coating for cables and wires.

G. Making fiber optic cables

Other uses of polyamide include use in the fiber optic cable industry. Due to the high resistance of polyamide against impact and damage, polyamide is used in these cables.

H. Use in the food industry

Polyamide grades are usually used for food packaging in the food industry. The reason for using these materials is that they can reduce the passage of oxygen and odor and increase resistance to puncture and damage.

Properties of polyamide

1. Flammability

Polyamides are considered flammable materials. However, most polyamides can be used within their application temperature range without problems.

2. Usable temperature range

The usable temperature range depends a lot on the type of polyamide. For example, polyamide six can be used at higher temperatures than polyamide 6.6. However, in general, it can be said that the practical temperature range of polyamides is between -30 and 90 degrees Celsius.

3. High strength

Having high strength is one of the mechanical properties of polyamides. But what exactly does this strength mean? Strength refers to the degree of resistance of polyamide against breaking or tearing. If compressive or tensile stress is applied to these materials, they can remain resistant to these stresses.

4. High flexibility

Another characteristic of polyamides is high flexibility. Flexibility means that if enough stress is applied to polyamides, they will not resist deformation and will change to the desired shape without breaking.

5. High resistance to petroleum solvents

In general, polyamides are very resistant to petroleum solvents, oils, and fuels. This resistance means that petroleum solvents, halogenated hydrocarbons, glycols, and other organic chemicals have almost no effect on polyamide.

6. Abrasion resistance

Abrasion means the erosion of a solid surface due to contact with another surface. A substance in contact with another body has a relative motion relative to it; its surface gradually decreases due to wear. Polyamide is resistant to this phenomenon and rarely wears out.

7. High impact

All objects are exposed to collisions and accidents with other objects, and each substance shows a specific resistance against these impacts according to its physical and chemical characteristics. In polyamides, the rate of impact ability is very high, which means that a lot of energy is required for the polyamide to be on the threshold of failure.

8. Resistant to cracking

High resistance to cracking has made polyamide popular in many industries. cracking in plastics such as polyamide is caused by the combination of tensile stress force and an exceptionally corrosive environment.

When cracking occurs, the polyamide surface is eaten very little, but localized cracks are formed on it. However, as mentioned, most polyamides are resistant to this cracking.

9. Ability to absorb water

Polyamides quickly absorb moisture and water compared to other thermoplastics. High humidity can cause polyamide erosion, so it is necessary to perform drying and dehumidification operations on polyamide.

The most commonly used simple polyamides

Polyamide 6,6 and 6 are the industry’s most essential and widely used polyamides. These two simple polyamides have excellent mechanical properties such as high tensile strength, high flexibility, excellent resistance, low creep, and excellent impact resistance. For this reason, they are widely used in various industries.

Comparison of types of polyamides

In the broad family of polyamides, there are several types of simple polyamides, each of which has its unique applications. Choosing the best of them depends on your needs and financial ability. Here we compare the types of these polyamides.

- The two polyamides that are used more than others are PA6 and PA66. These two are mainly used to produce fibers (in the textile industry) or films (in the packaging industry).

- Among simple polyamides, polyamide PA 4,6 has the best performance because it can replace metals in the industry and perform well in tough and special operating conditions.

- Most polyamides have an excellent ability to absorb water, which can sometimes cause problems. However, polyamide 6,9 absorbs moisture less than other polyamides. PA66 has the highest water absorption rate.

- If you don’t have financial restrictions, polyamides 6, 12, and 12 can be good options for you because these two polyamides, despite their high price, have many applications due to their excellent flexibility and low water absorption.

Please get in touch with our experts at Iran Petroleum for advice and purchase regarding your desired and suitable polyamide.

Leave a Reply