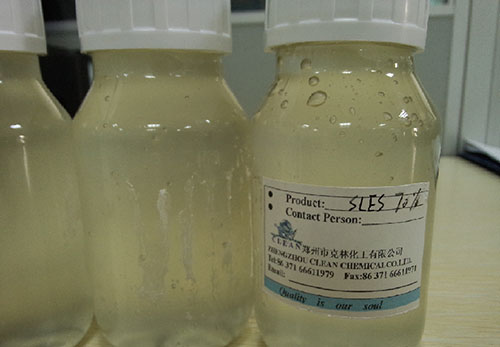

Texapon – SLES

Texapon is a white or yellow semi-transparent paste with a mild odor, which is sodium lauryl ether sulfate (SLES). It has good foaming properties, but the foam is light and not creamy. It is part of cosmetic and medicinal raw materials. This product is supplied in 110-200 kg barrels and exported in bulk.

What is Texapon?

Texapon is used in detergents to create foam and bubbles. Texapon acts as a basic surfactant and easily thickens with salt. This stable compound is derived from natural fatty alcohols that have a high molecular weight and waxy content.

In fact, in general, there are four types of anionic, cationic, nonionic and amphoteric surfactants, where Texapon is an anionic surfactant with excellent performance and no color. Sodium Lauryl Ether Sulfate (SLES) has excellent detergent, emulsification and plasticity properties. Texapon, sodium lauryl ether sulfate (SLES N70) is a colorless or light yellow viscous paste liquid that is odorless and easily soluble in water.

The content of Texapon is very low in salt and it has a very low viscosity when it is watery or diluted with water to the concentration of normal use. But we can adjust the viscosity by adding sodium chloride and appropriate alkanol amides. This product is marketed with two concentrations of 30 and 70%.

Texapon technical specification table

| Product Name | Texapon |

| Chemical formula | CH3(CH2)10CH2(OCH2CH2)nOSO3Na |

| Molecular weight | 288.38 g/mol |

| pH | Neutral equivalent to 7 |

| Density | 1.05 g/cm³ |

For each ethylene oxide group received, the amount of 44.05 g/mol is added to the molecular weight of Texapon. Therefore, for the sodium lauryl ether sulfate molecule that has 3 ethylene oxide groups, the molecular mass is calculated as 420.54 g/mol.

Properties of Texapon

Texapon has excellent inhibition, emulsification and plasticity. This chemical substance dissolves easily in water. It is also resistant to hard water and high biological decomposition.

Uses of Texapon

Texapon is used as a fat emulsifier, moisturizer, and detergent in cosmetics, pharmaceuticals, and toothpaste. This is also used as a research tool in protein biochemistry. Also used as a fat emulsifier, wetting agent and detergent.

Texapon is present in most cosmetic health products and body and head cleansers such as toothpaste, soap, shampoo, cream and lotion. This chemical substance is found in the market in two forms, Snow-White and normal, and the snow-white type is used to produce non-transparent and shell shampoos, as well as shell wash liquid.

Texapon is found in most detergents such as dishwashing liquid and industrial cleaners such as car washes and salt floors and oil removers and most hygiene products and lotions and body and head cleaners such as toothpaste, soap, shampoo, cream, in both forms. Liquid and non-liquid are used to remove fat as a foaming and cleaning agent and emulsifier of sticky materials and are among the primary ingredients of cosmetics and medicines.

Texapon types

Texapon manufacturing method

SLES is prepared by ethoxylation of dodecyl alcohol, which is industrially obtained from palm kernel oil or coconut oil. The resulting ethoxylate is converted to sulfuric acid half-ester, which is neutralized by converting to sodium salt. The corresponding surfactant is sodium lauryl sulfate (also known as sodium dodecyl sulfate or SDS) and is produced similarly, but without the ethoxylation step. SLS and ammonium lauryl sulfate (ALS) are commonly used as substitutes for SLES in consumer products.

What are the similarities and differences between SLS and SLES?

These substances are used in detergents such as: soaps, shampoos and other personal care products as surfactants, foaming agents and emulsifiers. Surfactants work because they have a hydrophilic part and a lipophilic part, and they make these substances able to clean fat, oil and other stain-causing substances when combined with water. Also, these compounds as emulsifiers cause all the components in the product to be combined with each other.

These materials are very similar to each other in terms of function, name or even structure, but there are also differences between them. The additional oxygen factor in SLES makes the difference between these two materials. This agent is added to SLES during a process called ethoxylation, causing a change in its function and sensitizing effect and causing its name to change from Lauryl to Lauret.

Texapon storage conditions

The suitable temperature for keeping Texapon is below 30°C to 10°C.

This material should be stored in a dry and cool place and avoid exposing it to sunlight or rain.

As mentioned in the MSDS of this product, this material can cause corrosion due to its high salt content. As a result, safety precautions must be observed when working with this substance. The contact of this material with skin and eyes can cause many risks. As a result, its contact with the skin and eyes should be avoided and safety gloves and safety glasses should be used during work so as not to be exposed to Texapon contamination.

Please contact our experts at Iran Petroleum for advice and purchase of products.

Leave a Reply